The construction industry is at the center of the global sustainability debate. Responsible for almost 40% of CO₂ emissions worldwide and producing more than three quarters of Austria’s annual waste, the sector faces an urgent need for innovation. Rising demand for housing and infrastructure makes it clear: We must rethink how we build – with smarter use of resources, lower emissions, and circular solutions.

Turning Waste Into Value

This is where ParaStruct, a start-up from Tyrol, comes in. With its pioneering approach, the company demonstrates how the principles of circular economy can be applied to construction. ParaStruct’s technology enables waste materials from the building sector (often mineral dusts, sands, or by-products) to be transformed into valuable resources. Their motto captures it best: “Cash the Trash.”

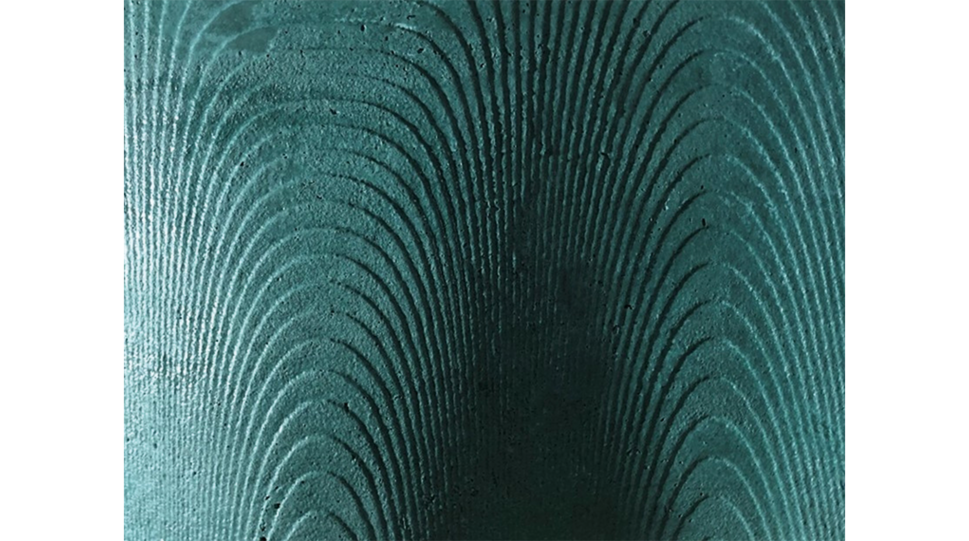

Innovation Through 3D Printing

At the heart of ParaStruct’s solution lies a unique combination of recyclable binding agents and additive manufacturing methods. By using 3D printing, they can reduce material consumption by up to 60% compared to conventional processes, while creating durable, aesthetically appealing components. One key innovation, the Ecomould material set, blends biogenic residues with mineral binders to produce fully recyclable, low-carbon building parts.

This approach not only reduces the carbon footprint by up to 60% compared to traditional cement-based materials, but also closes the loop by enabling components to be recycled at the end of their life cycle.

From Pilot Projects to Industry Impact

The potential of ParaStruct’s technology has already been proven. In partnership with voxeljet, they successfully tested the 3D printing of recycled construction waste, opening the door to scalable applications in interior design and laminating processes. Beyond construction, industries such as steel and wood are beginning to show strong interest in these solutions. Recognition at international awards, including those in the space sector, underlines the disruptive potential of the technology.

Shaping the Future of Building

Looking ahead, ParaStruct aims to expand its reach into additional industries and even extraterrestrial applications such as lunar and Martian habitats. The vision is ambitious: to demonstrate that circular and sustainable construction is not only possible on Earth, but also essential for future generations beyond it.

By rethinking the use of waste and integrating digital manufacturing methods, ParaStruct sets a benchmark for how innovation can transform the construction sector. With its “Cash the Trash” philosophy, the company shows how sustainability and economic efficiency can go hand in hand – paving the way toward a truly circular building industry.

Further Reading and References

For those interested in exploring ParaStruct’s innovative approach to sustainable construction, the following resources provide detailed insights and real-world examples:

- Visit the official ParaStruct website for an overview of their technology and projects.

- Austria Wirtschaftsservice highlights ParaStruct’s journey and support within Austria’s innovation ecosystem.

- brutkasten features in-depth articles, including: “We must halt the destruction of our planet before moving on to the next” and a detailed profile on how ParaStruct is using 3D printing to transform the construction industry sustainably.

- 3printr reports on the collaboration between Voxeljet and ParaStruct, showcasing 3D printing with recyclable, processed construction waste for mold making.

- Puls4 & ORF’s 4gamechangers (June 10, 2024, from 39:00) provides a video segment demonstrating ParaStruct’s impact on sustainable construction practices.

These resources illustrate how ParaStruct combines cutting-edge technology with environmental responsibility—an approach that aligns with broader goals of sustainable innovation in the construction sector.